Steam is essential in many of today’s industrial processes. Saturated steam production may not be the most suitable for the facility, making it necessary to increase its temperature while maintaining pressure, in order to prevent the formation of drops of water in suspension that can damage the equipment downstream. Superheated steam is the most suitable in such cases, as it provides a large input of energy and remains above condensing temperature.

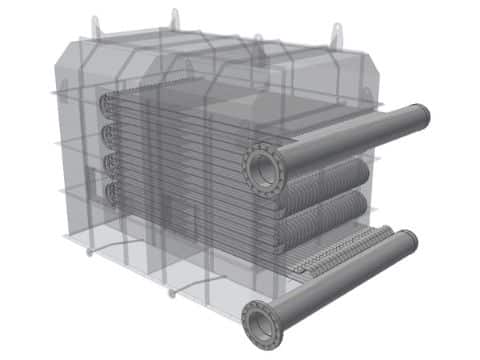

Thermal superheaters are a common solution. These consist basically of joined tubes in which the steam produced by the boiler flows through, heated by the combustion gases from the burner. They are usually integrated into the boilers and supplied as a single unit.

How to get superheated steam?

Another way of superheating steam is using independent equipment such as electric superheaters. These consist of a pressure vessel containing an electrical element that heats the steam from the boiler. Unlike in the previous case, this additional heating of the steam is achieved without burning fuel, thus reducing emissions around the facility.

Both solutions provide a supply of steam at constant temperature and quality, delivering a precise amount of energy. Furthermore, avoiding liquid drops is essential in certain facilities, such as in power plant turbines.

At Cerney boilers we industry leaders. Do not hesitate to contact us for more information.