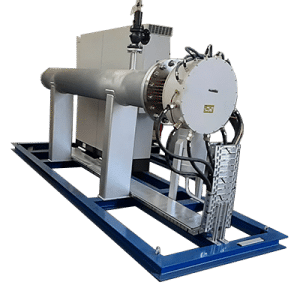

Thermal degasser

Thermal degasser

- Thermal deaerators or degassers are basically used to remove the oxygen present in the feed water.

- They are made up of two bodies: the top one, where water degassing is performed, and the bottom one, where the degassed water is stored.

- The top body or degassing head, properly speaking, is made of stainless steel. It is made up of two deaeration zones and a device for purging non-condensables.

We manufacture thermal degassers tailored to each customised situation. Contact us for information about your project.

How does a degasser work?

- The water to be degassed (condensate, treated water and condensate return) is introduced into the degassing head from the top through a spray nozzle, which atomises the water inside the degassing head itself. The water rapidly reaches its operating temperature, and the initial degassing process is then carried out, during which the majority of the oxygen is eliminated.

- The water then passes into the second degassing zone, the mixing chamber. The stainless steel chamber comprises two concentric bodies, with perforations on the inside to facilitate the flow of steam, which comes into contact again with the descending water as it rises towards the degassing head. This water therefore undergoes energetic washing by this steam that bubbles through it, further reducing the content of non-condensable gases. Finally, the degassed water passes to the storage tank on its downward path.

Types of Cerney complementary equipment

Contact us

You can write to us with any questions you may have, and we will be pleased to get back to you as soon as possible.